High Alumina Fire Brick is made by high sintering selected bauxite chamotte by advanced process with strict quality control at 1420-1530℃. We can supply you SK36, SK37, SK38, SK40 refractory alumina bricks with factory price. The indicators of these products are shown in the table below.

Welcome to inquiry us about high alumina bricks price, size, index and anything you want to know.

Performance Characters Of High Alumina Fire Bricks:

1. High temperature resistant.

2. Chemical erosion resistant.

3. Thermal stability.

4. Slag resistance.

| Item/Grade | SK-36 | SK-37 | SK-38 | SK-40 |

| AL2O3% (≥) | 55 | 65 | 70 | 82 |

| Fe2O3% (≤) | 2 | 2 | 2 | 2 |

| Refractoriness(SK) | 36 | 37 | 38 | 40 |

| Refractoriness underload, 0.2MPa, °C (≥) | 1450 | 1480 | 1530 | 1600 |

| Apparent porosity (%) | 20-23 | 20-23 | 20-22 | 18-20 |

| Bulk density (g/cm³) | 2.25-2.4 | 2.3-2.5 | 2.4-2.6 | 2.5-2.7 |

| Cold crushing strength ,MPa (≥) | 45 | 50 | 60 | 70 |

Also, we have SK30, SK32, SK34, SK35 refractory clay bricks to choose. Their aluminum content is lower than high alumina bricks, and the use temperature is lower, but the price is cheaper. If your kiln is not demanding, you can also choose refractory clay bricks. 【MORE】

التطبيقات Of High Alumina Fire Bricks:

1. Furnaces of metallurgy industry, heat treatment furnace.

2. Furnaces of chemical industry and construction industry.

3. Furnace of incineration of garbage, recirculating fluidized bed furnace.

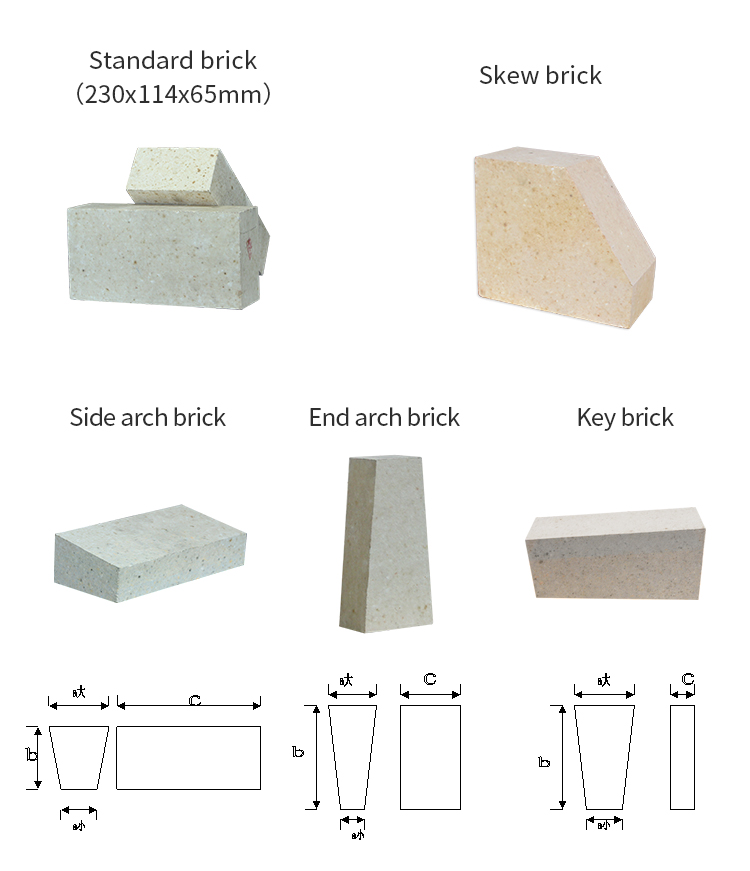

Standard size Of High Alumina Fire Bricks:

230x114x65mm. This product can be customized on color, size and shape, ect. Welcome to OEM and ODM.

We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.