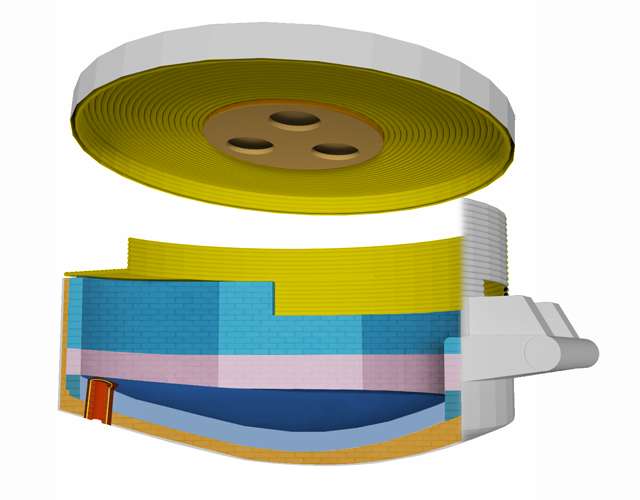

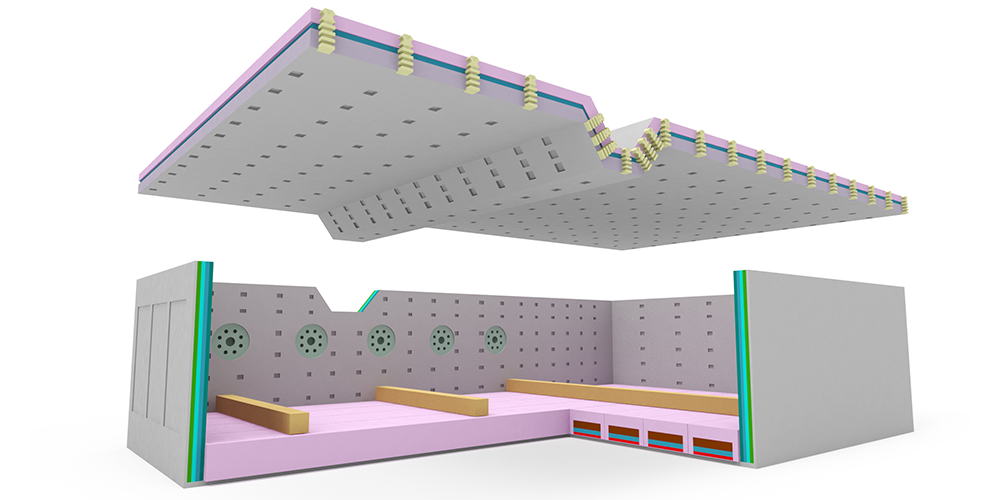

Kerui Refractory delivers refractory solutions for melting and holding furnaces used in the production of aluminium and aluminium alloys for many years. Our products are produced using high-grade raw materials which are designed for all areas of the furnaces.

Application: Melting and Holding Furnace

By utilizing our long experience in supplying refractory products for aluminium furnace in abroad, Kerui Refractory has been known for offering the best refractory solution with our complete product range that has been designed and developed to meet the specific needs in each area of aluminium melting and holding furnaces.

As a solution to minimize the dross formation and the penetration from aluminium and its alloys during the operation, Kerui Refractory has developed a series of aluminium non-wetting low cement castable. Such product series feature superior aluminium and alkaline resistance, excellent strength to withstand severe mechanical impact, and thermal shock resistance for high fluctuation of operating temperatures.

Silicon Carbide Based Monolithic Refractories

Silicon Carbide Based Monolithic Refractories include Silicon Carbide Castable, Silicon Carbide Ramming Mix, Silicon Carbide Refractory Mortar, Refractory Mortar For Composite Bricks.

Alumina-silica Monolithic refractories

Alumina-silica monolithic refractories include dry impermeable castable, high-strength castable, insulating castable, and insulation refractory mortar.

Low Cement Castable

Using high-quality bauxite and flint clay as the main raw material and calcium aluminate cement as the binder, this castable has the characteristics of high strength and stable performance.

Non-stick Alumina Castable

This castable is made of super-grade alumina as the main raw material, and pure calcium aluminosilicate cement is used as the binder. By adding anti-wetting agent and optimizing the matrix composition structure, it has good resistance to aluminum liquid infiltration.

High Alumina Plastic Refractory

This product is made of high-quality bauxite as the main raw material and phosphate as the binder. It has the characteristics of long shelf life, good thermal shock resistance, and good construction performance.

Lichtgewicht isolerende gietmassa

The castable is made of mullite lightweight aggregate, floating beads as main raw materials, and aluminate cement is used as the binder. It has the characteristics of good thermal conductivity, high strength and so on. It is widely used for heat insulation of kilns.

Contact us! Request refractory solutions and price for your needs. info@krefractory.com, +86 19036973888

Customer Case

Refractory for ladle in Taiyuan, Chi na

SK38 223 Tons

Muiilte castable 59 Tons

Ceramic fiber blanket 186m3

…

Ladle monolithic refractory in Thailand

Magnesia carbon brick 295 Tons

Muiilte insulating brick 90 Tons

Ceramic fiber board 86 m3

…

Refractory for ladle in Shanxi, China

Ladle castable 106 Tons

Ladle nozzle 325 Tons

Ladle nozzle block 210 Tons

…