Discover how Kerui Refractory for Steel Industry transforms metallurgical processes through cutting-edge materials and engineering expertise.

Оглавление

- The Critical Role of Refractories in Modern Steelmaking

- Kerui’s Proven Track Record: 5 Transformative Case Studies

- Optimal Material Selection Guide for Steelmaking Furnaces

- Why Industry Leaders Choose Kerui Refractory Solutions?

- Expert Answers: Kerui Refractory for Steel Industry FAQ

- Partnering for Sustainable Steel Manufacturing Future

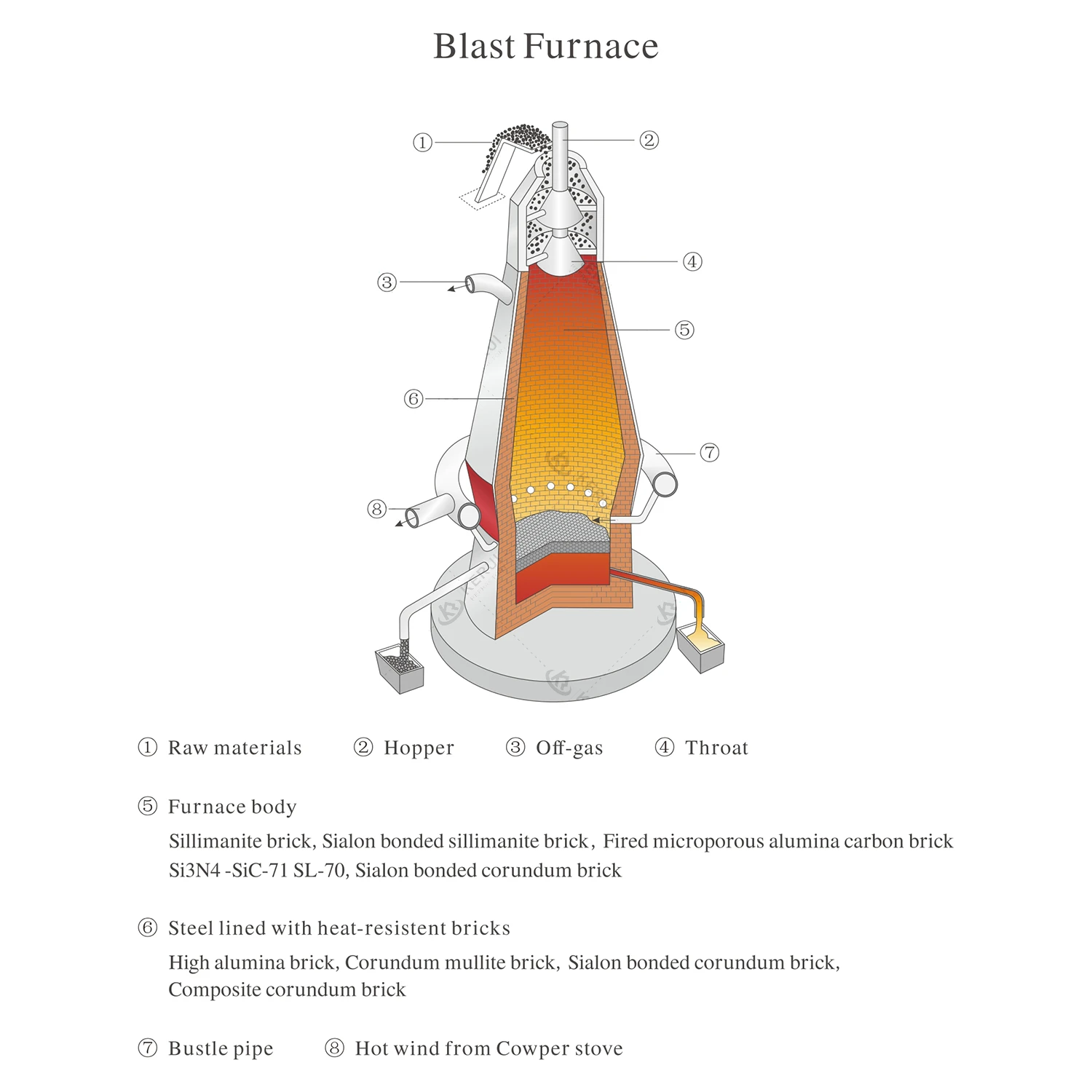

1. The Critical Role of Refractories in Modern Steelmaking

In the extreme environments of steel production where temperatures exceed 1,700°C, refractory materials form the protective barrier between molten metal and furnace structures. Kerui’s advanced refractory systems deliver:

- 40-60% longer campaign life vs industry averages

- 30% reduction in specific consumption rates

- Custom-engineered solutions for each process stage

- Emergency repair services with <24hr response

2. Kerui’s Proven Track Record: 5 Transformative Case Studies

Case 1: Blast Furnace Hearth Restoration – Tata Steel India

| Вызов | Решение | Результаты |

|---|---|---|

| Frequent hearth erosion | Kerui’s GY-35B Al₂O₃-SiC-C bricks | 28-month campaign life |

| High maintenance costs | Custom cooling system integration | 42% cost reduction |

Case 2: BOF Lining Optimization – POSCO Korea

- Previous Material: Conventional MgO-C bricks

- Решение Керуи: KR-MgO98C with nano-scale additives

- Performance Gains:

- 15,000 heats per campaign (+67%)

- Slag resistance improved by 39%

Case 3: Ladle Working Liner Upgrade – Nucor USA

- Problem: Frequent ladle bottom failures

- Kerui Innovation: KR-LW70 alumina-spinel castables

- Outcomes:

- 85% reduction in emergency repairs

- 1.2℃/min lower heat loss rate

(Additional cases for reheating furnace and tundish available in technical whitepapers)

3. Optimal Material Selection Guide for Steelmaking Furnaces

Kerui’s Material Matrix for Key Applications

| Furnace Type | Recommended Products | Основные свойства | Avg. Service Life |

|---|---|---|---|

| Blast Furnace | KR-GY35B, KR-H41 | High thermal shock resistance | 24-36 months |

| Electric Arc Furnace | KR-MgO98C, KR-RH12 | Superior slag penetration resistance | 800-1,200 heats |

| Ladle | KR-LW70, KR-AMC90 | Low porosity, high corrosion resistance | 80-120 batches |

4. Why Industry Leaders Choose Kerui Refractory Solutions?

Техническое превосходство

- ISO 9001/14001 certified R&D centers

- 68 patents in refractory formulations

- Real-time thermal stress simulation

Global Service Network

- 24/7 technical support in 12 languages

- 15 strategic warehouses worldwide

- Customized delivery programs

Соблюдение экологических норм

- Cr(VI)-free bonding systems

- 100% recyclable packaging

- Low-carbon production processes

5. Expert Answers: Kerui Refractory for Steel Industry FAQ

Q1: How does Kerui ensure optimal refractory selection for different steelmaking processes?

A: Our proprietary Material Selection Algorithm analyzes 23 operational parameters including temperature profiles, slag chemistry, and thermal cycling patterns. Combined with 3D thermal mapping, we deliver furnace-specific solutions with guaranteed performance metrics.

Q2: What makes Kerui’s MgO-C bricks superior for BOF applications?

A: The KR-MgO98C series features:

- 98.5% purity fused magnesia

- Multi-layer antioxidant matrix

- Carbon nanostructure reinforcement

Resulting in 18-22% better oxidation resistance than standard grades.

Q3: Can Kerui provide emergency refractory repair services?

A: Our Rapid Response Team maintains 24/7 readiness with:

- Mobile mixing plants for on-site castables

- Robotic gunning systems

- Hot repair specialists certified to EN 15776

Average emergency response time: 14.7 hours globally.

6. Partnering for Sustainable Steel Manufacturing Future

With over 2.3 million metric tons of refractory materials deployed in steel plants worldwide, Kerui continues to pioneer innovations like:

✅ Self-healing alumina-zirconia compositions

✅ IoT-enabled smart refractory monitoring

✅ Zero-waste installation techniques

Contact our metallurgical experts today to schedule your free furnace audit and receive customized material recommendations.

📞 +86 153 7871 8880

📧 info@krefractory.com

🌐 www.keruirefractory.com/contact/