Reading Navigation

- What Are Blast Furnace Refractories?

- Types of Blast Furnace Refractories

- Key Product Parameters & Performance Metrics

- Critical Applications in Modern Steelmaking

- FAQs About Blast Furnace Refractories

- Why Choose Kerui Refractory?

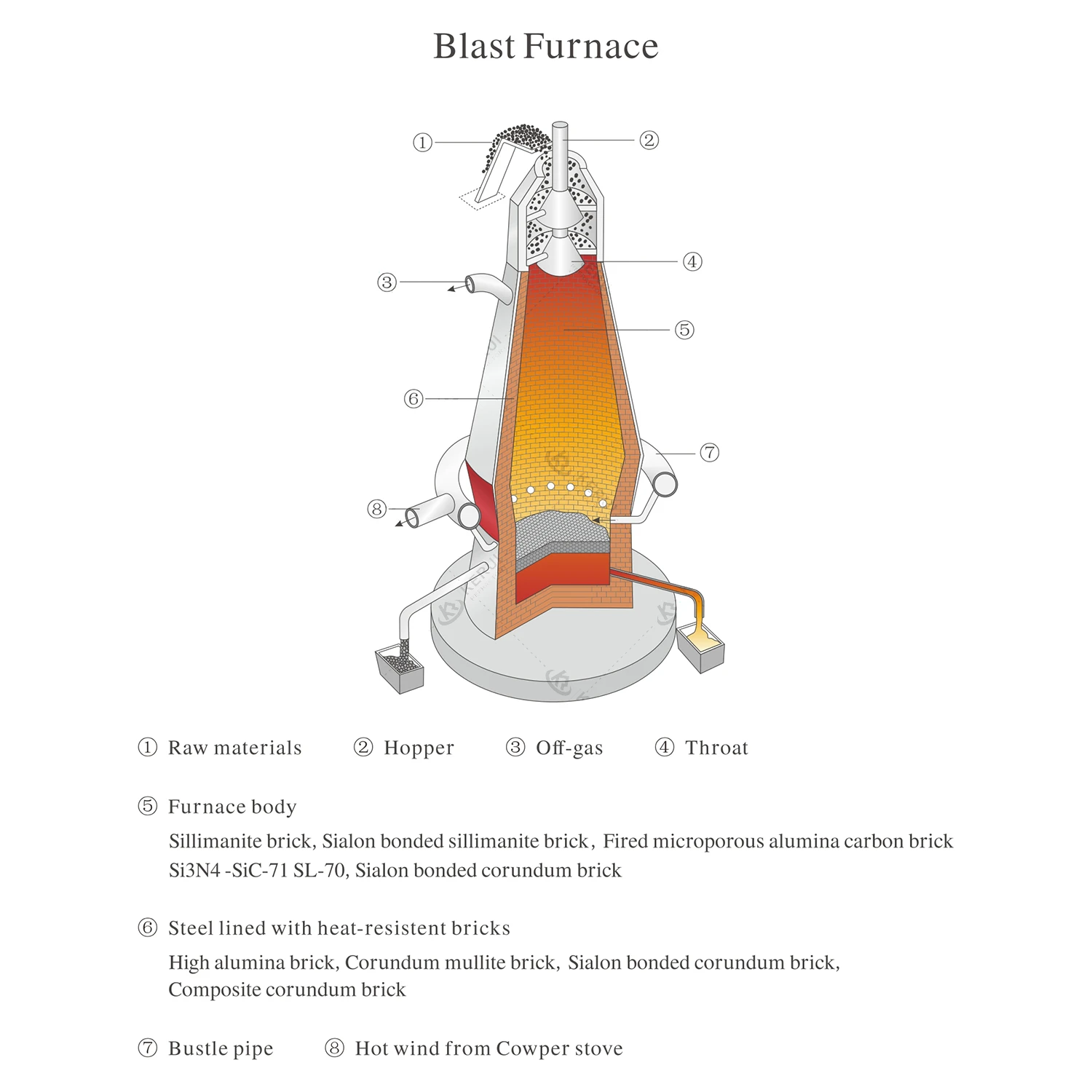

What Are Blast Furnace Refractories?

Blast furnace refractories are specialized heat-resistant materials engineered to withstand extreme temperatures (up to 2,000°C), chemical corrosion, and mechanical wear in iron and steel production. These materials form the protective lining of blast furnaces, ensuring operational efficiency, safety, and longevity.

Types of Blast Furnace Refractories

1. Silica-Based Refractories

- Склад: 94-97% SiO₂ with calcium oxide binders

- Максимальна температура обслуговування: 1,650°C

- Додатки: Furnace stack and upper zones

2. Alumina-Silica Refractories

- Склад: 45-80% Al₂O₃, balance SiO₂

- Максимальна температура обслуговування: 1,750°C

- Додатки: Hearth and bosh regions

3. Silicon Carbide Refractories

- Склад: SiC (70-90%) + nitride bonding

- Максимальна температура обслуговування: 1,800°C

- Додатки: Tuyere zones and hot blast systems

4. Magnesia-Based Refractories

- Склад: MgO (85-95%) with carbon additives

- Максимальна температура обслуговування: 2,000°C

- Додатки: Slag line protection

5. Carbon-Composite Refractories

- Склад: Graphite + resin/pitch binders

- Максимальна температура обслуговування: 2,200°C

- Додатки: Furnace crucibles and tap holes

Key Product Parameters & Performance Metrics

| Параметр | Кремнезем | Alumina-Silica | Silicon Carbide | Магній | Carbon-Composite |

|---|---|---|---|---|---|

| Теплопровідність | 1.2 | 1.8 | 15 | 5.5 | 40 |

| Compressive Strength | 35 MPa | 50 MPa | 90 MPa | 75 MPa | 25 MPa |

| Porosity (%) | 18 | 12 | 8 | 10 | 5 |

| Стійкість до шлаку | Середній | High | Very High | Чудово. | Помірний |

Critical Applications in Modern Steelmaking

- Hearth Lining: Carbon composites prevent molten iron penetration.

- Bosh and Stack Zones: Alumina-silica refractories resist alkali attacks.

- Tuyere Systems: Silicon carbide linings endure high-velocity hot air (1,200°C).

- Tap Hole Maintenance: Magnesia-carbon blocks enable rapid repair cycles.

- Blast Furnace Campaign Life: Premium refractories extend operational periods from 8 to 15+ years.

FAQs About Blast Furnace Refractories

Q1: What factors reduce blast furnace refractory lifespan?

A: Alkali/vapor corrosion, thermal cycling, and slag/iron erosion are primary culprits. Kerui Refractory’s pre-fired blocks and nano-coatings mitigate these issues through enhanced density (≤12% porosity) and micro-crack resistance.

Q2: How to choose between silica vs. alumina refractories?

A: Silica suits acidic slag environments (FeO-rich), while alumina excels in basic slag (CaO/MgO) conditions. Kerui’s engineers provide free slag analysis to match materials to your furnace chemistry.

Q3: Can blast furnace refractories be repaired mid-campaign?

A: Yes. Kerui’s patented gunning mixes and hot-spray technologies allow in-situ repairs without full shutdowns, saving 30-50% in downtime costs.

Q4: What’s the ideal replacement cycle for hearth linings?

A: Carbon-based linings typically last 10-12 years. Kerui’s UltraDense™ blocks have achieved 15+ years in Tata Steel’s furnaces through iso-static pressing and 99.9% graphite purity.

Q5: Do blast furnace refractories require pre-treatment?

A: Kerui’s pre-fired blocks (1,450°C for 72+ hours) eliminate 95% of initial shrinkage, ensuring stable geometry during commissioning.

Why Choose Kerui Blast Furnace Refractories?

With ISO 9001:2015-certified manufacturing and 20+ years of metallurgical expertise, Kerui Refractory delivers:

- Precision Engineering: Laser-guided sizing (±0.5mm tolerance)

- Rigorous QC: 23-stage inspection protocol, including XRD mineralogy analysis

- Global Track Record: 420+ blast furnace installations across 18 countries

- 24/7 Technical Support: Remote furnace monitoring and emergency dispatch

Ready to Optimize Your Blast Furnace Performance?

📧 Email: solutions@keruirefractory.com

🌐 Submit RFQ: Kerui Contact

Boost campaign life by 40% with Kerui’s next-gen blast furnace refractory solutions – where innovation meets reliability.