Reading Navigation

- Introduction to Steel Ladle Refractory Linings

- Types of Steel Ladle Refractory Linings

- Key Product Parameters & Performance Metrics

- Critical Applications in Modern Steelmaking

- FAQs About Steel Ladle Refractory Linings

- Why Choose Kerui Refractory?

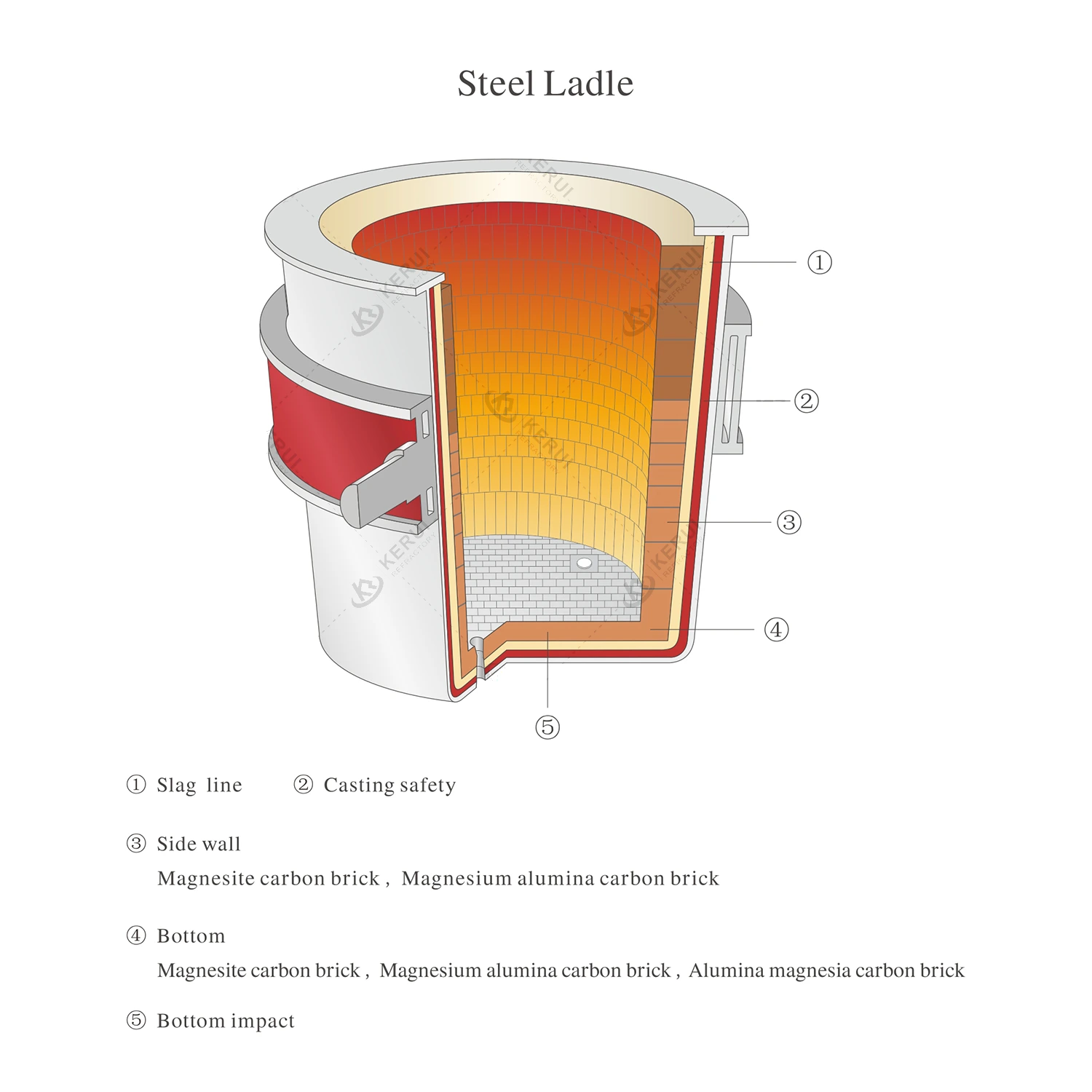

Introduction to Steel Ladle Refractory Lining

Steel ladle refractory lining form the protective barrier between molten steel (1,600–1,700°C) and the ladle structure. These linings must withstand extreme thermal shocks, chemical corrosion, and mechanical abrasion while maintaining structural integrity. With global steel production exceeding 1.95 billion metric tons annually, the demand for high-performance steel ladle refractory lining solutions has never been greater.

Types of Steel Ladle Refractory Lining

1. Magnesia Carbon (MgO-C) Lining

- 组成: 70–90% magnesia, 10–20% graphite

- 最高工作温度: 1,750°C

- 主要功能:

- Superior slag resistance

- Excellent thermal shock stability

- 25–40% longer campaign life vs traditional bricks

2. Alumina Magnesia Carbon (AMC) Lining

- 组成: 50% Al₂O₃, 30% MgO, 15% C

- 最高工作温度: 1,700°C

- 应用:

- Ladle slag lines

- High-alloy steel production

3. Zirconia-Based Lining

- ZrO₂ Content: 60–85%

- 导热性: 2.1–2.8 W/m·K

- Special Properties:

- Ultra-low wettability by molten steel

- Ideal for >200 heats in stainless steel ladles

| Material Type | Thickness Range (mm) | Installation Method | Avg. Lifespan (Heats) |

|---|---|---|---|

| 镁碳砖 | 150–300 | Dry Gunning | 80–120 |

| Alumina Magnesia Carbon Castables | 200–400 | Vibration Casting | 100–150 |

| ZrO₂ Preforms | 75–150 | Mechanical Fastening | 150–200 |

Key Product Parameters & Performance Metrics

Critical Quality Indicators:

- 冷碾强度: ≥35 MPa

- 表观孔隙率: ≤15%

- Thermal Expansion Coefficient: 5.8–7.2 ×10⁻⁶/°C

- Slag Penetration Resistance: Class 4 (ASTM C874)

Kerui Refractory’s proprietary KR-9X™ formulation achieves:

- 18% higher thermal shock cycles (ASTM C1171)

- 31% reduction in lining erosion rates

- ISO 9001-certified manufacturing processes

Critical Applications in Modern Steelmaking

1. Secondary Metallurgy Stations

- RH degasser linings

- CAS-OB alloying zones

2. Special Steel Production

- Stainless steel ladle bottoms

- Silicon steel slag pockets

3. Continuous Casting Systems

5 Essential FAQs About Steel Ladle Refractory Linings

Q1: How often should steel ladle refractory lining be replaced?

A: Replacement cycles vary from 50–200 heats depending on:

- Lining material grade (MgO-C vs ZrO₂)

- Steel grade being processed (carbon vs high-alloy)

- Slag basicity (CaO/SiO₂ ratio)

Kerui’s predictive maintenance algorithms can extend campaigns by 22–35% through real-time wear monitoring.

Q2: What causes premature failure in ladle linings?

A: Primary failure mechanisms include:

- Thermal spalling from rapid temperature changes

- Chemical attack by FeO-rich slags

- Structural cracking due to improper preheating

Our field studies show 68% of failures can be prevented through proper installation protocols.

Q3: How to select the optimal lining thickness?

A: Use this formula:

T(min) = (Q × t)/(k × ΔT)

Where:

- Q = Heat flux density (W/m²)

- t = Required holding time (hrs)

- k = Thermal conductivity (W/m·K)

- ΔT = Temp gradient (°C)

Kerui engineers provide free thickness optimization simulations for qualifying orders.

Q4: Can ceramic fiber modules replace traditional linings?

A: While ceramic fibers (1260–1400°C rating) work for some preheating zones, they lack the:

- Mechanical strength for slag line duty

- Chemical stability against basic slags

Our hybrid designs integrate fiber insulation with dense castables for 19% energy savings.

Q5: What’s the ROI of upgrading to advanced linings?

A: A typical 120-ton ladle using Kerui’s KR-9X™ linings achieves:

- $58,400 annual savings in refractory costs

- 140+ additional heats per campaign

- 23% reduction in steel contamination

Why Kerui Refractory Leads in Ladle Lining Solutions

25 Years of Metallurgical Expertise

- 420+ successful ladle lining projects globally

- R&D center with 37 patented formulations

Unmatched Quality Assurance

- XRF chemical analysis on every batch

- 三维激光扫描实现尺寸精度

- ISO 14001 environmental compliance

End-to-End Technical Support

- Thermal profiling of existing linings

- Slag chemistry optimization consulting

- Robotic installation training

立即行动

电子邮件 info@krefractory.com for:

- Free sample testing of your current linings

- Customized CAD lining layouts

- Volume discounts on orders >50 tons